SIPs (Structural Insulated Panels)

SIPs have been our regular exterior wall system since we built our first home in 1995. Structural Insulated Panels are an engineered building system made with two skins of Oriented Strand Board (OSB) separated by a thick Expanded Polystyrene (EPS) core.

Like an “I” beam, you get a very strong wall system without the need for vertical studs running through the exterior walls which are poor insulators and cause heat loss. SIPs are also excellent in that the dew point, where moisture condenses, is inside the living space where circulation systems can safely remove moisture. Other systems that use fiberglass with rigid or spray foam on the outside have dew points inside the wall where moisture can produce mold. SIPs were in development from the mid 1930′s until the 1960′s when they were refined and perfected.

One of the most unique features of Structural Insulated Panels (SIPs) is that there are none of the vertical studs that are found throughout the length of a typical stick built home. Vertical studs are not good insulators… there’s a potential air leak point at each stud and in the fiberglass insulation used. Basically, SIPs make a home function like a thermos, keeping the inside of the home warmer in the winter and cooler in the summer.

Benefits of SIPs

- Saves money – reduces heating and cooling requirements by 40% to 60%.

- Safer – 2 to 3 times stronger than traditional stick framing.

- Healthier – no off gassing.

- More comfortable – quieter, tighter and less drafty.

- Easier on the environment – made using recycled material and 75% less dimensional lumber than a stick frame home.

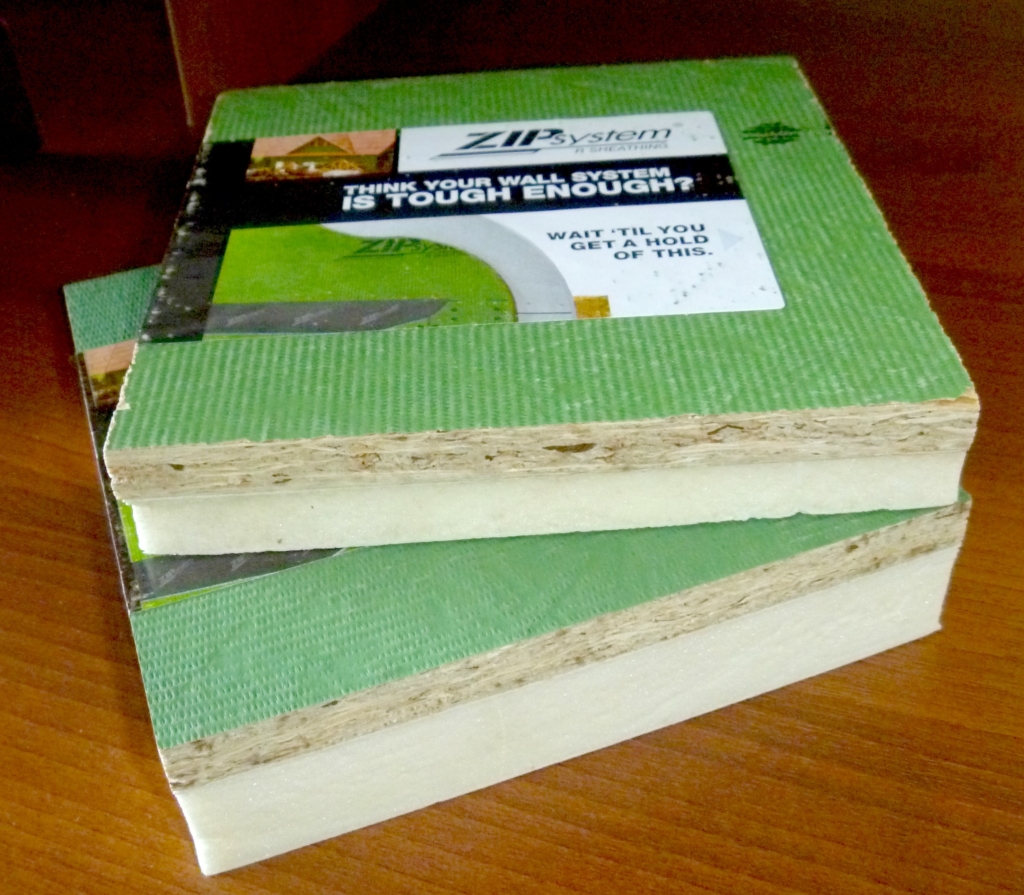

Benefits of ZIP System

- Allows for a continuous R10 or R13 foam insulation (necessary in our climate).

- Creates an air tight seal around the house.

- Keeps condensation out of the structure.

- WRB (water resistive barrier) is built in, facilitating quick, smooth installation.

- Performs as well as a 4” or 6” SIP wall but is more cost effective.

Reducing heat loss through the foundation

Up to 37% of heat loss in a home is through an uninsulated basement. That’s one reason why, in every home we build, we super insulate both under slab and on the foundation walls. Not only does this save energy costs, but it creates a lower level space that is dry, comfortable and usable year-round.

Super Insulated Foundations

While we have experimented with different foundation systems over the years, we’ve found the most cost effective and foolproof method is applying foam over a poured concrete wall. We have developed a method of attaching 2, 4, 6 or 8 inches of expanded polystyrene (EPS) foam to the exterior of a standard poured wall, then waterproofing. This method provides the desired insulation results for maximum energy efficiency at a reasonable cost.

Insulated Concrete Forms (ICFs)

ICFs are made of Expanded Polystyrene panels with a spacer system. The foam forms are left in place after the concrete cures to leave behind an insulated wall system. We have used this product and found it to be a very effective method for building a well-insulated foundation. However, the pour must be done properly or pockets of air can be formed, creating a breakdown in energy efficiency and, possibly, stability.

Roof Insulation

A high performance home requires a well thought out plan for the roof insulation. PEA Builders utilizes three different methods to satisfy this requirement:

- SIPS Roof – Only used when it makes sense, based on the design and roof pitch.

- Direct Spray Foam – I-joists with spray foam insulation attached to the underside of the roof deck to create a hot roof.

- Hybrid System – Our most common method which combines a thin layer of spray foam insulation, usually 2-5”, on top of the drywall ceiling. Cellulose insulation is then blown over the top of the foam to create an R60.

Windows

PEA Builders utilizes a variety of windows based on an individual customer’s needs and budget. We only choose windows that fit our high-performance standard. Triple pane windows are your best choice when possible. They have gas injected into the two air fill spaces between three panes of glass, significantly increasing their energy efficiency. They come in fiberglass, composite or vinyl, some with foam filled frames and sashes. Windows can also be tuned for passive solar and solar tempering, with high solar heat gain collecting the sun’s southern heat.

Generally speaking, we categorize windows by Good, Better and Best or Premium so that we can give customers with varying budgets the best quality possible.

Here is a basic breakdown:

CONTACT US

262-506-9616